|

Research-Production Company «Uniservice», «SAUTER» company engineering сenter, offers a new fire safety systems equipment set .

Set contains:

- programable controller EYR203F001 measuring and controling inputs/outputs;

- uninterruptible power supply СКАТ-2004, of ПО «Бастион» company (г. Ростов на Дону) with in-built accumulator;

- auxiliary successive connection port for connection with other controllers and dispatching computer.

This set is certificated in accordance with НПБ 75-98, НПБ 57-97 and is meaned in first place for fire fighting and antismoke systems.

Moreover, it can be used in fire-alarm systems, since controller has fire informers loops connection inputs.

For the sake of application convenience this set can be delivered with a number of accessory:

- operator console with alphnumeric display,

- graphical operator panel (Touch Panel),

- digital inputs and outputs units (DI and DO).

CONTROLLER

Controller EYR203F001 is the set major component. This controller is programable and contains:

32 bit processor, program nonvolatile RAM 3 Mbit, microprogram ROM 4 Mbyte, EPROM for warehousing programes 512 Mbyte, accumulator, in-built power source, input/output channels, including 10 analogous inputs (AI), 4 analogous outputs (АO), 8 digital inputs (DI), 6 digital outputs (DO).

Input/output channels number can be increased by means of auxilary EYZ267F001 type DI units (4 channels in unit) and EYZ268F001 type DO units (3 channels in unit).

DI units are connected to analogous inputs. General controller DI number can therefore be increased up to 48. DO uints are connected to controller analogous outputs.

General DO number can therefore be increased up to 18.

Active fire informers loops are connected to controller analogous inputs. Domestic and imported informers, similar to ИП-212-5 informers, can be used.

Number of informers in the loop - no more then 6 (max current in loop 60 mA). Number of loops on one controller - up to 4. Loop break and short circuit are provided for.

Passive informers of ИП-109 type and others are connected to digital inputs successively.

STRUCTURE

The programable controllers Sauter main advantage is an arbitrary complexity fire safety system creation opportunity.

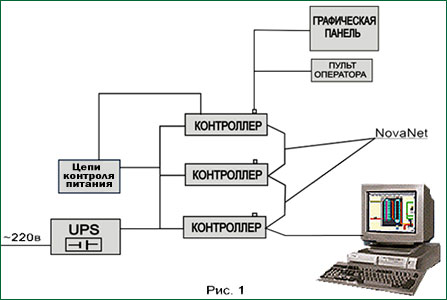

In one system can be used a number of controllers, united with Nova Net (pic.1) flow line

and working in accordance with general system algorithm.

Controllers exchange data with each other, with dispatching computer, operator consoles for remote monitoring and control, with various data transmission mediums.

Operator console and graphical panel can be connected to any controller, but at that information is exchanged between them and all of system controllers.

Operator console allows to obtain information on fire occurrence, fire-extinguishing means actuation, emergency conditions etc.

Graphical panel, besides of listed functions, allows to represent fire fighting system facilitys conditions in form of mnemonic diagrams.

All equipment, included in set, is programed by means of various software:

- controller programing package with FBD - units library;

- Upper system level programing package (dispatching computer) - Nova Pro, Nova Pro Open;

- programming aids for operator consoles, graphical panels, telecommunication facilities.

In considered set are included ГОСТ required means of self-control and external circuit conditions monitoring:

- 220 V power monitoring;

- accumulator discharge monitoring;

- voltage presence on fire fighting facilities main and reserve inputs monitoring;

- controling channels actuation monitoring and others.

Offered by Research-Production Company «Uniservice» set provides fire safety equipment Customers

with following opportunitys:

- Various fire safety systems creation on the basis of reliable units, corresponding ISO 9001 standards

and having warranty exploitation period 3 years.

- Low cost of the set makes it more obtainable for russian consumer.

- Fire safety systems construction ability, which can without any additional facilities exchange data with Sauter company building engineering equipment automation systems, and

using various communication facilities - standard communications protocols (LON, Siemens, Modbus and others) -

integrate it with other producer companys systems.

|